Celsius : Manufacturer of equipments for process industries

Company and skills

As a result of its long history of works in fine chemicals, CELSIUS benefits from an unquestionable savoir-faire in the world of process equipment. The engineering of equipment requires a vast knowledge and experience in such various fields as processing design, chemical design, fluid mechanics, thermodynamics, hydraulics, thermal technology and process command.

Process development

CELSIUS designs the industrial processes of tomorrow and thus builds equipment that will be in operation for a long time

Engineering

CELSIUS develops its own designing tools and carries out in-house PID schematic studies, mass balances, thermal balances, simulations of transient regimes, implantation studies

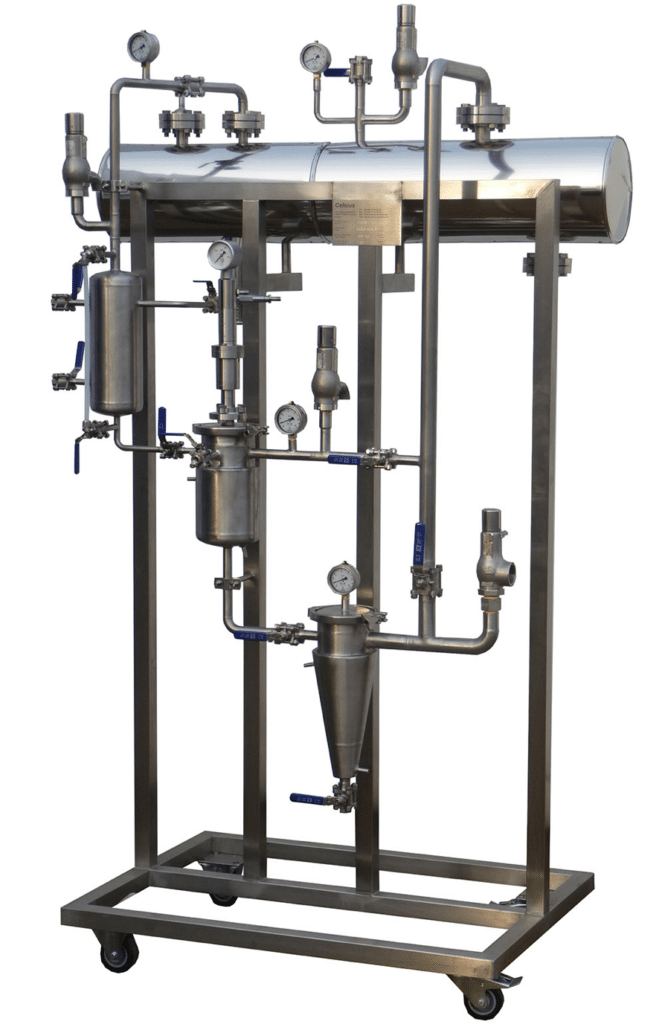

Pressure vessels and assemblies

For the needs of its processes, CELSIUS designs and requires its sister company AUSTENITE for the manufacture of exchangers and double jacket pressure vessels according to category I to IV of PED

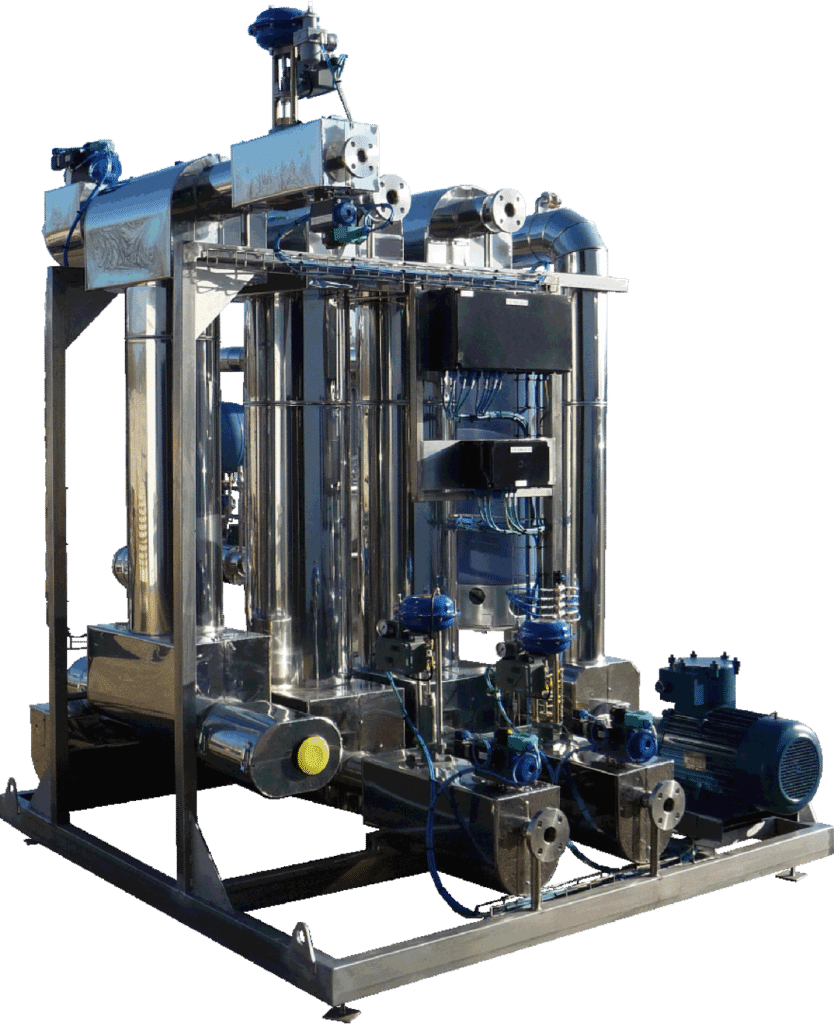

Assembly of packages

CELSIUS assembles in its own workshops complete skids fully piped, insulated and wired. They are ready to be installed and connected to minimize site time and costs on site. The complete technical file for operation and maintenance includes the CE certificate of conformity and the Installation Qualification protocol for validation by the FDA.

Automation

CELSIUS equipment is, at the customer's request, either automated by the operator himself on the basis of the functional analysis of CELSIUS, or automated by CELSIUS with a specific program on an automaton chosen by the client, or automated on a CELSIUS PLC with a standardized and proven program

Process modeling

The CELSIUS automatism program is completed by a simulation of the transient process regimes according to the laws of fluid mechanics and thermodynamics. This allows the regulation parameters to be preset and to minimize the commissioning time

They trust us

The advantages of our products

The design of our equipment is optimized to maximize productivity, reduce energy and material consumption and ensure safety in all circumstances. Complete construction of plug-and-play skids in our own workshop minimizes costs and time for on-site installation and commissioning

Process modeling

The phases of the process in transient or continuous regime are modeled according to the laws of thermodynamics and fluid mechanics. This modeling makes it possible to optimize the design of our devices and anticipate the settings during industrial commissioning

Installation studies

The assembly of the skids is designed in a 3D model according to the site layout constraints to minimize dimensions. The skids are open for easy access to each component during maintenance

Skills

In order to ensure the complete process function, we manage ourselves in our design office and our workshop all the necessary abilities: engineering, layout studies, sheet metal work, piping, assembly, heat insulation, electricity and automation

CE certification

The equipment is delivered with a CE firm plate and an overall certification according to PED 2014/68 / EU and, if required, according to ATEX 2014/34 / EU

FDA validation

The equipment are delivered with an Installation Qualification protocol after Factory Acceptance Test, the first stage of installation validation to be carried out by the FDA on the operating site. The complete technical file for installation, commissioning and maintenance is delivered in a paper copy and a CD-Rom copy